Flow injection analysis systems typically operate at high sensitivity. The technology involves introducing, under the force of a peristaltic pump, a precisely measured volume of liquid sample from the sampler into a continuously flowing carrier stream. An injection valve with a fixed-volume sample loop or an injection valve with a fixed time period determines the injected volume of sample. A carrier stream sweeps the sample out of the loop and into the manifold where it disperses. The concentration gradient formed is detected continuously by (in this case) a colour reaction that occurs in the presence of continuously flowing reaction solutions (see Section 4130 of APHA 2005 for further details of the technology).

Figure 5.2. A continuous, segmented flow sheet (AutoAnalyzer I/II technology) for water-soluble chloride.

The colorimetric chemical reaction involved is identical to that of Method 5A2a; i.e. Cl– reacts with mercuric thiocyanate to produce mercuric chloride, liberating thiocyanate ions. In the presence of ferric salts, these thiocyanate ions produce a characteristic orange-like colour, the intensity of which is proportional to the Cl– concentration. In common with Method 5A2a, Br–, I–, cyanide, thiosulfate and nitrite will interfere positively if present, which is unlikely in most natural (uncontaminated) soils. Expect Methods 5A2a and Method 5A2b to yield virtually identical results.

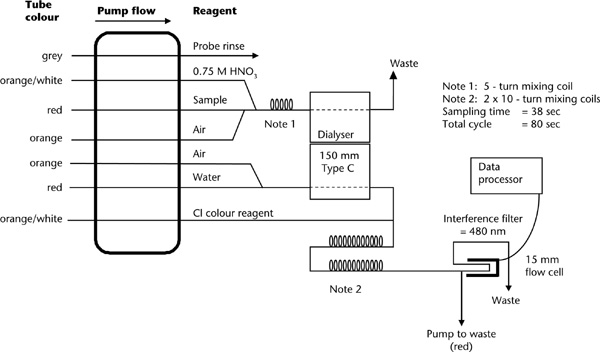

Figure 5.3. A micro-bore continuous flow manifold for water-soluble chloride.

Figure 5.4. Example of a generic FIA manifold for water-soluble chloride. Tubing volumes are only examples, which may be scaled down proportionally as required and in accord with manufacturer’s recommendations.

Use reagents and standard solutions from Method 5A2a for guidance, or as advised by the manufacturer. All reagents should be free of particulates. Alternatively, vacuum filter before use through a 0.45 μm membrane filter known not to be contaminated by Cl–. Degas reagents before use if necessary.

Prepare 1:5 soil/water suspensions as described in Method 3A1. Filter or centrifuge a suitable aliquot for automated FIA. These should be free of particulates. If necessary, pass the extract through a 0.45 μm membrane filter known not to be contaminated by Cl–.

Ensure individual components of the FIA–Cl– manifold are assembled in accord with manufacturer’s recommendations, guided by Figure 5.4.

‘Condition’ the system before use by pumping reagents and relevant standard solutions. Make a final check on instrument settings, then determine Cl– concentrations in soil extracts directly from standard solutions run on commencement and as required throughout the batch of unknown soil extracts. A good, second-order polynomial calibration can be expected. Use deionised water as the wash solution and to dilute soil extracts of high Cl– concentrations.

Report water-soluble Cl– (mg Cl/kg) on an air-dry basis.